Ever tried painting an aluminum surface, only to watch the paint peel or flake off within weeks? If so, you’re not alone. Aluminum’s sleek, non-porous exterior might look ideal for painting, but it actually poses unique challenges that set it apart from other metals. The secret to a flawless, durable finish? It all starts with the right aluminum primer.

Aluminum is prized for its lightweight strength and corrosion resistance, making it a favorite in industries from automotive to architecture. But here’s the catch: aluminum naturally forms a thin, invisible oxide layer the moment it’s exposed to air. While this oxide layer protects the metal from corrosion, it’s also extremely smooth and chemically inert—meaning standard paints and primers simply won’t stick well. Imagine trying to paint a pane of glass; without the right preparation, the result is uneven, short-lived, and prone to peeling.

This is where a primer for aluminum surfaces comes in. An aluminum primer is a specially formulated product designed to bond to the metal’s tough oxide layer. Its core function is to create an adhesive, paint-friendly surface that ensures the topcoat grips tightly and evenly. Applying the right primer solves common problems like:

Beyond adhesion, aluminum primers often add a layer of corrosion protection, helping your painted surfaces withstand weather, UV rays, and even industrial chemicals. The result? A finish that looks professional and lasts far longer than paint alone.

Ready to transform your aluminum projects? In this complete guide, you’ll learn:

By understanding the science behind aluminum primer and following proven preparation and application steps, you’ll ensure your next aluminum project stands the test of time—no matter where or how it’s used.

When you paint wood or steel, standard primers usually do the trick. But have you ever wondered why painting aluminum is so much trickier? If you’ve experienced paint that peels off aluminum in sheets or bubbles after a single season outdoors, you’re not alone. The root of these problems with painting aluminum lies in the metal’s chemistry—and understanding it is the first step to a flawless, lasting finish.

Aluminum’s surface is unique. The moment it’s exposed to air, it develops a thin, transparent oxide layer. Sounds protective, right? In fact, this oxide is what gives aluminum its legendary resistance to rust and corrosion. But here’s the catch: this same layer is also extremely hard, smooth, and chemically stable. In other words, it’s nearly impossible for standard primers or paints to grip onto it.

Imagine trying to stick tape to polished glass—that’s what it’s like for paint on untreated aluminum. Standard primers are designed for porous or slightly rough materials, not for a surface that actively resists bonding. As a result, the paint sits on top of the oxide layer rather than fusing with the metal. Over time, this weak bond is easily broken by temperature changes or moisture.

While specialized primers solve adhesion challenges, there’s another approach: leveraging aluminum’s natural oxide layer through anodizing. This electrochemical process transforms the surface into a hard, integrated finish that needs no paint. Explore the science in: The Anodizing Advantage: Built-in Protection for Aluminum.

Now, why is a specialized primer non-negotiable for painting?

What happens if you skip the right primer or use a standard one? You’ll notice a series of frustrating issues that compromise both appearance and durability. Here’s a breakdown of the most common problems caused by improper surface preparation and priming:

These issues aren’t just cosmetic—they shorten the lifespan of your project and can lead to costly repairs. For example, aluminum siding or boat hulls exposed to weather can quickly deteriorate if the protective paint layer fails.

The solution? A primer engineered for aluminum’s unique surface. Specialized primers—often called self-etching or epoxy primers—are formulated to chemically interact with the oxide layer, breaking through its resistance and creating a textured, adhesive-friendly base. This step is absolutely critical for long-term performance. Without it, even the best paint will fail to adhere, no matter how carefully you apply it.

In short, understanding aluminum oxidation and primer chemistry is the key to avoiding common pitfalls and achieving a finish that stands up to time, weather, and everyday use. Next, we’ll dive into the types of primers that make all the difference for your aluminum projects.

When you’re choosing a primer for aluminum, the decision often comes down to two main types: self-etching primer for aluminum and epoxy primer for aluminum. At first glance, they might seem similar—both are designed to help paint stick to tricky surfaces—but their chemistry, application, and performance are quite different. So, which should you use for your next project?

Imagine you’re restoring an old aluminum boat or prepping a car panel. The primer you pick will determine how well your paint job lasts through seasons, sun, and storms. Here’s a breakdown of what sets these two primer types apart:

| Feature | Self-Etching Primer | Epoxy Primer |

|---|---|---|

| Bonding Mechanism | Uses acid to chemically etch the aluminum’s oxide layer, creating a micro-rough surface for paint adhesion. | Relies on a two-part resin system that forms a tough, waterproof barrier and bonds mechanically to a sanded surface. |

| Preparation Needed | Minimal; can be applied to bare, degreased metal. Quick and convenient for small jobs or spot repairs. | Requires thorough sanding or media blasting for best adhesion. Surface must be clean and dry. |

| Drying & Curing | Fast-drying; ready for topcoat or another layer in minutes to an hour. Convenient for quick turnarounds. | Slower to cure; may take several hours to fully harden. Once cured, cannot be dissolved by solvents. |

| Water & Corrosion Resistance | Not water-resistant. Offers little to no corrosion protection—if the topcoat chips, moisture can reach the metal. | Highly water-resistant and forms a moisture barrier. Excellent for marine, outdoor, or industrial use. |

| Best Use Cases | DIY repairs, automotive touch-ups, and small projects. Great for speed and ease, but not for harsh environments. | Restoration, marine, architectural, and long-term protection projects. Ideal for high-value or exposed aluminum surfaces. |

| Durability | Moderate. Can be reversed or softened by solvents. Not recommended where moisture exposure is likely. | Excellent. Once cured, creates a permanent, tough layer that resists solvents and moisture. |

Picture this: You’re refinishing a set of aluminum patio chairs. If you want a quick fix and the chairs will stay mostly dry, a self-etching primer for aluminum might be enough. But if you’re restoring a boat hull or prepping architectural aluminum for outdoor use, an epoxy primer for aluminum is the safer bet. Its superior resistance to water and corrosion means your hard work will last much longer (source).

Still unsure? As a rule of thumb, the more valuable or exposed your project, the more you’ll benefit from epoxy’s robust protection. Next, we’ll take a closer look at the science behind how self-etching primers bond to aluminum, helping you understand why proper surface preparation is so important.

Ever wondered why some paint jobs on aluminum last for years while others start peeling with the first sign of rain? The answer lies in the science of how self-etching primer works—a process that transforms aluminum’s stubborn, slick surface into the perfect foundation for long-lasting paint.

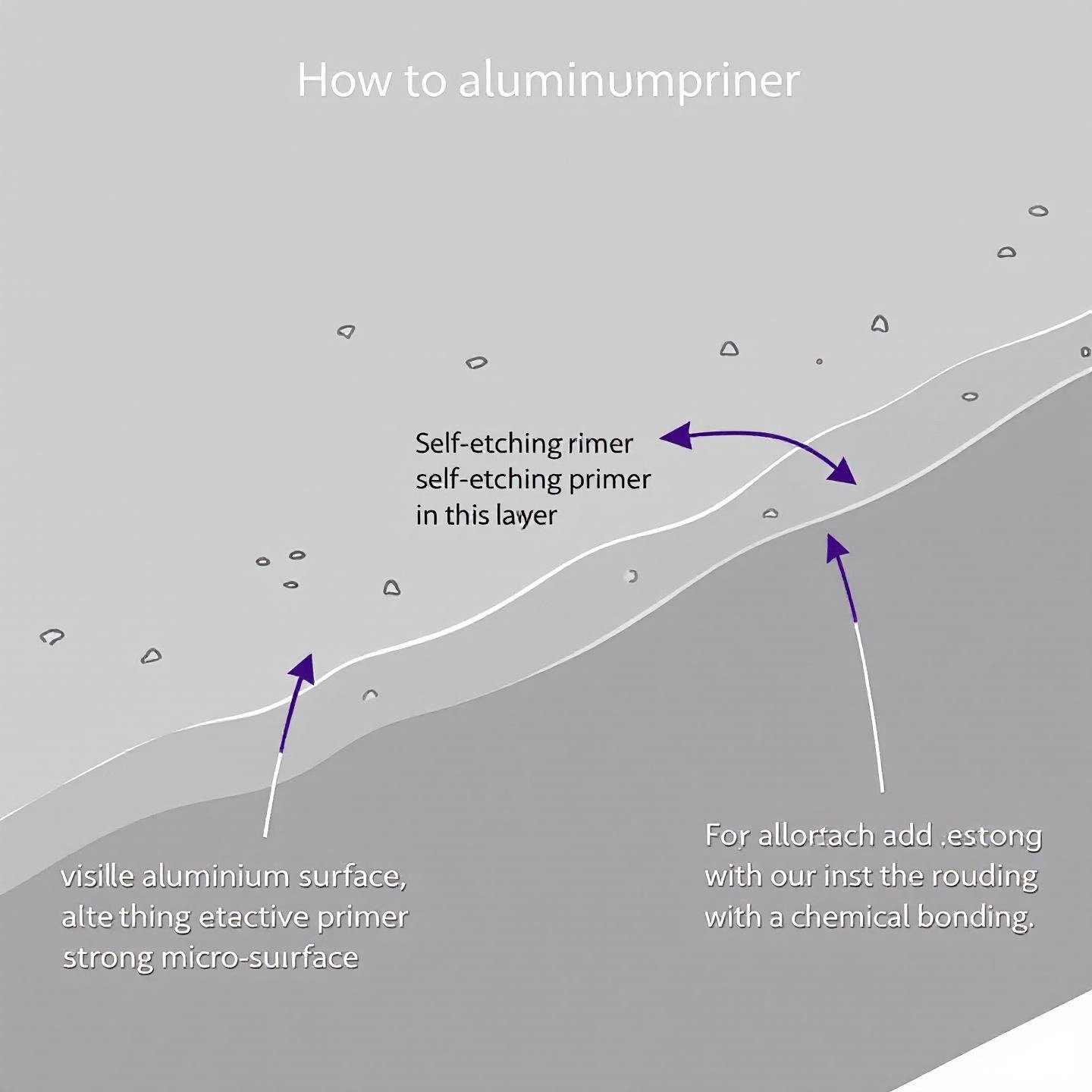

Let’s start with the challenge: aluminum instantly forms a tough oxide layer when exposed to air. This layer is both protective and problematic—it’s chemically inert and incredibly smooth, making it nearly impossible for standard paints or primers to stick. Here’s where self-etching primers come in.

Imagine sanding a surface, but on a microscopic level. This etching process is the first step to unlocking strong aluminum primer adhesion.

Once the acid has done its job, the primer’s resin component takes over. Here’s what happens next:

This process is similar to what’s used in advanced dental adhesives, where self-etching primers create a durable interface between tooth and filling material by both etching and infiltrating the surface (source).

Without this chemical and mechanical bond, even the best paint will eventually fail—especially on surfaces exposed to the elements or physical wear. By understanding how self-etching primer works, you can see why skipping this step is never worth the risk. The etched surface and resin-filled valleys mean your paint is anchored for the long haul, resisting peeling, flaking, and bubbling.

Next, we’ll walk through the practical steps to prepare and prime your aluminum surface for maximum durability and a flawless finish.

Ever wondered why some aluminum finishes look perfect for years while others start peeling or bubbling within months? The secret isn’t just in the paint—it’s in the prep. Whether you’re restoring a boat, refinishing window frames, or tackling industrial projects, meticulous surface preparation for aluminum painting is the foundation for a flawless, durable finish. Let’s break down exactly how to apply aluminum primer, step by step, so your next project stands the test of time.

Imagine the rigorous standards required for high-value applications like those at Shengxin Aluminum, where industrial profiles are used in rail transit, automotive, and architectural projects. In such environments, every step of surface treatment and priming is meticulously controlled to ensure maximum durability and flawless appearance—because even a minor flaw can compromise safety or performance. By following these same careful steps, you can achieve professional-grade results at home or in the workshop.

With your aluminum surface now expertly primed, you’re set up for a topcoat that lasts. Next, we’ll explore how to choose the right primer for demanding environments, like marine applications, where protection against water and corrosion is critical.

When you picture an aluminum boat slicing through waves or moored for months in saltwater, it’s easy to see why regular paint and primer just won’t cut it. The marine environment is relentless—think constant moisture, salt spray, and the threat of corrosion and biofouling. So, how do you ensure your boat’s hull stays protected and your paint job lasts? The answer lies in selecting the right aluminum boat primer—a product engineered to meet the unique challenges of life on the water.

Aluminum is naturally corrosion-resistant, but in the harsh conditions of lakes, rivers, and especially saltwater, even the toughest hulls are at risk. Moisture can sneak beneath poorly bonded paint, leading to bubbling, peeling, and—worst of all—accelerated corrosion. Add in the constant threat of marine organisms clinging to the hull, and you have a recipe for rapid deterioration if you don’t use the right primer.

Unlike primers for household or automotive use, aluminum boat paint primer must do more than simply help paint stick. It needs to create a waterproof barrier, block out corrosive salts, and provide a foundation for antifouling paints that keep barnacles and algae at bay.

Ever wondered why so many boatyards and marine professionals insist on two-part epoxy primers below the waterline? Here’s what sets them apart:

Imagine prepping your boat for a season in the marina. A two-part epoxy primer not only shields the metal from salt and water but also provides the ideal surface for antifouling paint, which is your best defense against barnacles and algae.

Let’s say you’re refinishing an aluminum fishing boat. After cleaning and etching the hull, you mix your two-part epoxy primer according to the directions, apply it within an hour of prepping the surface (to prevent new oxidation), and allow it to cure. Once tacky, you follow up with an antifouling bottom paint. This system—when done right—creates a multi-layer defense that keeps your boat looking sharp and performing well, season after season.

Choosing the right aluminum boat primer is more than a technicality; it’s your first line of defense against the elements. In the next section, we’ll compare some of the most trusted brands and products, helping you find the best fit for your specific project and environment.

Ever stood in the paint aisle, staring at rows of cans, and wondered, “Which aluminum primer is actually going to work for my project?” With so many options—Rust-Oleum, SEM, Krylon, and more—it’s easy to get overwhelmed. Let’s break down what sets these best aluminum primer brands apart, and which one might be the perfect fit for your needs.

When you’re tackling a home project—say, refinishing a set of patio furniture or giving a small boat a facelift—rustoleum aluminum primer is often the go-to choice. Why? It’s widely available, affordable, and comes in both spray and brush-on formulas. Users on boating forums praise its ease of use and the fact that it can be paired with Rust-Oleum’s professional series paints for a complete system. One DIYer shared, “I used rustoleum aluminum primer with the white cap, by two top coats. I didn’t sand between coats, and the results were great. The best part? The whole project cost less than $60!”

Looking for something tailored for automotive or specialty metalwork? SEM and Krylon are two other brands frequently recommended by professionals and hobbyists alike. SEM’s self-etching primers are known for their strong chemical bond to bare aluminum, making them a staple in body shops for prepping panels before painting. Krylon’s line offers fast-drying, easy-to-use primers that are ideal for small metal parts, crafts, or touch-ups.

| Brand | Best Use Case | Application Method | Strengths |

|---|---|---|---|

| Rust-Oleum | DIY, outdoor, small boats | Spray, brush, spray gun (thinned) | Affordable, easy to find, user-friendly |

| SEM | Automotive, professional repair | Spray | Strong adhesion, self-etching, industry trusted |

| Krylon | Crafts, touch-ups, small metal parts | Spray | Fast-drying, accessible, great for small jobs |

Imagine you’re prepping a set of aluminum window frames for a modern architectural project. You’d likely want the assurance of a product trusted by pros—something like SEM for the primer layer, by a compatible topcoat. For large-scale, high-performance needs, manufacturers like Shengxin Aluminum bring industrial expertise to the table, ensuring every surface is primed and finished to exacting standards.

With so many brands and formulas out there, the key is to match your choice to your project’s demands—balancing ease of use, durability, and environmental exposure. Next, we’ll look at specialty primers like zinc chromate, designed for the toughest industrial and aerospace applications.

Ever wondered why some aircraft and heavy machinery seem to defy the test of time—even in the harshest environments? The answer often lies in the use of specialty coatings, and among the most storied is zinc chromate primer for aluminum. But what makes this industrial aluminum primer so effective, and why is it reserved for only the most critical applications?

Imagine you’re tasked with protecting a jet’s wing or a subway car’s structural frame. Ordinary primers simply won’t cut it. Zinc chromate is a chemical compound (ZnCrO4) that appears as a yellow-green powder when used as a primer. Developed in the 1920s for industrial use, it quickly became a go-to solution for the aerospace and automotive industries due to its unique ability to bond with aluminum and prevent corrosion (source).

Sounds like the perfect solution, right? But here’s the catch: zinc chromate contains hexavalent chromium (Cr(VI)), a substance known to be highly toxic and carcinogenic. Prolonged exposure—especially inhaling dust or spray—can lead to serious health risks, including cancer and tissue damage. Because of this, its use is now tightly regulated and typically limited to professional or industrial settings with strict safety protocols.

Despite the risks, zinc chromate remains the gold standard for certain critical applications—especially where maximum corrosion protection is non-negotiable. For example, aerospace manufacturers and heavy industry still specify zinc chromate for:

These are scenarios where the cost of failure is simply too high, and only the most robust industrial aluminum primer will do. Companies like Shengxin Aluminum, which supply aluminum profiles for rail transit and other high-performance sectors, rely on such industrial-grade primers to meet demanding durability and safety standards.

Given the health and environmental concerns, many industries are shifting toward non-chromate alternatives—such as advanced epoxy or phosphate primers—that offer strong protection with fewer hazards. Still, for legacy systems and the highest-risk environments, zinc chromate maintains its reputation as the ultimate shield.

In short, if you’re working on a project that demands elite, industrial-grade protection—and you have access to professional safety equipment and protocols—zinc chromate primer for aluminum may still be specified. For most other applications, safer modern primers offer a balance of performance and peace of mind. Up next, we’ll help you distill all these options into a simple framework for choosing the best primer for your specific project.

Still unsure which is the best primer for aluminum in your situation? With so many options—self-etching, epoxy, marine-grade, and even specialty industrial primers—it can feel overwhelming. Let’s break it down into a practical, step-by-step decision framework, so you can confidently choose the right product for your next project.

Imagine you’re standing in the paint aisle, or prepping your workspace at home. Ask yourself: What am I painting, and where will it be used? Use the following checklist to narrow down your options:

| Project Type | Recommended Primer | Key Features |

|---|---|---|

| Decorative (indoor furniture, art, crafts) | Self-etching primer | Quick-drying, easy to apply, strong adhesion for light use |

| Automotive (car panels, wheels, restoration) | Self-etching or epoxy primer | Self-etching for spot repairs; epoxy for full panels and maximum protection |

| Marine (boats, docks, water-exposed parts) | Two-part epoxy primer (marine-grade) | Superior corrosion resistance, waterproof, compatible with antifouling topcoats |

| Architectural/Structural (window frames, railings, siding) | Epoxy or industrial-grade primer | Long-term durability, weather resistance, excellent adhesion |

| Industrial/Aerospace | Specialty primer (e.g., zinc chromate, phosphate) | Elite corrosion protection, professional application only |

By following this framework, you’ll know exactly how to choose aluminum primer that matches your goals, environment, and project value. Next, we’ll wrap up with a recap of best practices and a few expert tips to ensure your finish is flawless and built to last.

Ever wondered why some aluminum paint jobs look showroom-new for years, while others start peeling after just one season? The difference is almost always in the prep and the products you choose. If you want truly professional results, here’s a quick recap of the professional aluminum painting tips that separate flawless finishes from frustrating failures.

"A flawless aluminum finish isn’t luck—it’s the result of careful preparation, the right products, and following a proven aluminum primer application guide every single time."

So, the next time you tackle an aluminum project—whether it’s a boat hull, window frame, or a piece of industrial equipment—remember these best practices. Clean, abrade, and prime with purpose. With the right approach, you’ll enjoy a finish that’s as tough as it is beautiful, and built to stand the test of time.

For most aluminum surfaces, a self-etching or epoxy primer is recommended. Self-etching primers chemically bond to aluminum, while epoxy primers offer superior corrosion resistance—ideal for outdoor, marine, or high-wear applications. Always match the primer to your project’s environment and demands for best results.

Aluminum forms a non-porous oxide layer that standard primers can't bond to, leading to issues like peeling, flaking, and poor adhesion. Specialized aluminum primers, such as self-etching or epoxy types, are designed to overcome this barrier and create a durable, adhesive surface for paint.

Rust-Oleum aluminum primer is suitable for DIY and small-scale projects, especially above the waterline. For marine or continuous outdoor exposure, a two-part epoxy primer is usually preferred to ensure maximum corrosion resistance and long-term durability in harsh environments.

Proper preparation includes cleaning the surface thoroughly, removing grease and oxidation, lightly sanding with fine-grit sandpaper, and wiping down with a solvent. This meticulous process ensures the primer bonds correctly and delivers a long-lasting finish.

Zinc chromate primers are reserved for critical industrial or aerospace projects due to their elite corrosion protection. They require strict safety measures because of health risks and are not intended for consumer or standard DIY use.

Интернет Сервис

Интернет Сервис 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360