When you think of materials that are both versatile and durable, extruded aluminum often comes to mind. This remarkable material plays a crucial role in numerous industries, from automotive to aerospace, and even in everyday consumer products. But what exactly is extruded aluminum, and why is it so significant across various sectors?

Extruded aluminum is created through a process where aluminum is pushed through a die to form specific shapes. This method enhances the metal's natural properties, making it lightweight yet strong, corrosion-resistant, and highly malleable. These attributes are why industries rely heavily on extruded aluminum for applications that require both precision and durability.

Now, imagine the impact of selecting the right supplier in this aluminum extrusion industry. Choosing reliable extruded aluminum suppliers is paramount to ensuring that the final products meet the highest quality and performance standards. A dependable supplier not only provides high-quality materials but also offers consistency in production, timely delivery, and the capability to meet custom specifications.

In the competitive landscape of the aluminum extrusion industry, the right supplier can significantly influence a project's success. They ensure that the products are manufactured to exact specifications, which is critical in industries where precision is non-negotiable, such as in aerospace or electronics. Moreover, a good supplier will also assist in optimizing costs without compromising on quality, thereby adding value to your supply chain.

In summary, extruded aluminum is a cornerstone material in many industries, and selecting the right suppliers is a critical step in leveraging its full potential. As we delve deeper into the world of aluminum extrusion, we'll explore the processes, applications, and key players that shape this vital industry.

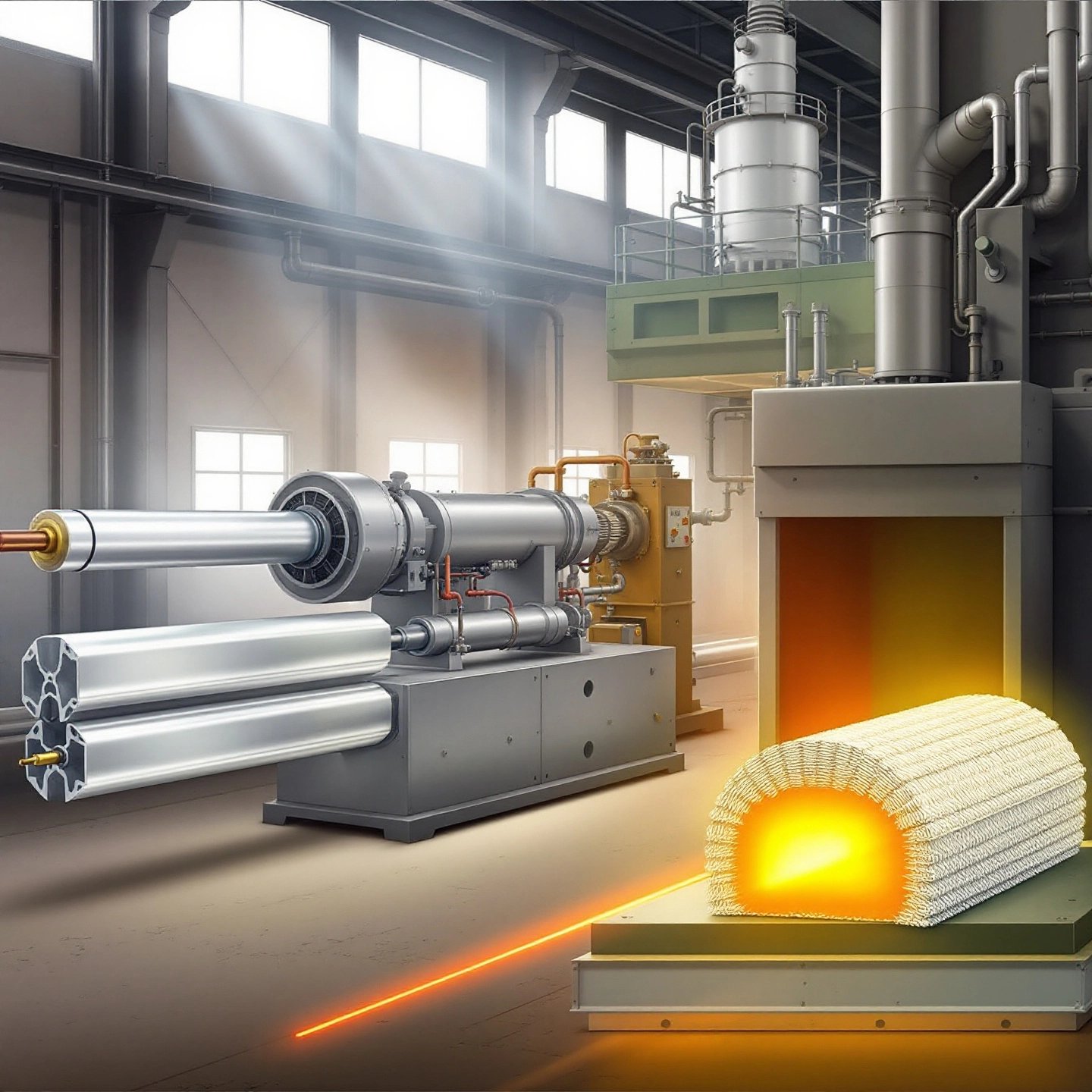

Imagine squeezing toothpaste from a tube; this simple action mirrors the fundamental principle of the aluminum extrusion process . This process involves pushing heated aluminum alloy through a specifically shaped die to create profiles with a consistent cross-section. But how does this seemingly straightforward process translate into a cornerstone of modern manufacturing?

The journey of aluminum extrusion begins with selecting the right alloy, typically from the 2000, 6000, or 7000 series, which are known for their strength and versatility. The alloy is then heated until it becomes malleable, a state that allows it to be pushed through the die with a hydraulic press. This step is crucial as it defines the shape and size of the extruded product, whether it be a solid, hollow, or semi-hollow profile.

The benefits of aluminum extrusion are vast. This process allows for remarkable design flexibility, enabling the creation of complex shapes that would be difficult or impossible to achieve with other manufacturing methods. Additionally, extruded aluminum products boast superior strength-to-weight ratios, making them ideal for applications where both durability and lightweight properties are essential.

Moreover, the extrusion process is highly efficient and cost-effective, as it minimizes material waste and allows for high-volume production. This efficiency is further enhanced by the ability to combine extrusion with other fabrication techniques, such as machining and drilling, to meet precise specifications.

As we move forward, we'll explore the specific industries that rely on these advantages, showcasing the diverse applications of extruded aluminum.

Extruded aluminum is a material of choice across numerous industries due to its unique combination of strength, lightweight, and versatility. But what makes it indispensable in sectors like automotive, construction, aerospace, and electronics? Let's delve into the specific applications of aluminum extrusion in these key industries.

These industries using extruded aluminum demonstrate the material's versatility and adaptability. Whether it's enhancing vehicle performance, supporting architectural innovation, or advancing aerospace technology, the applications of aluminum extrusion are as diverse as they are essential. As we continue, we'll explore the criteria for selecting the right suppliers to ensure these applications reach their full potential.

When it comes to choosing aluminum suppliers, making an informed decision is crucial for ensuring the quality and success of your projects. But what are the key criteria you should consider to select the best supplier for your needs? Let's explore the essential factors that can guide your selection process.

First and foremost, assess the supplier's commitment to quality. Look for certifications such as ISO 9001, which indicate a rigorous quality management system. Suppliers with such certifications are more likely to deliver consistent and reliable products. Ensure they have robust quality control processes in place, including regular inspections and testing throughout the production cycle. This attention to detail helps guarantee that every extruded product meets the specified standards.

Next, evaluate the supplier's production capabilities. Do they have the necessary equipment and technology to handle your specific requirements? Consider their ability to produce complex shapes and designs, as well as their capacity for high-volume production. Suppliers with advanced extrusion capabilities can offer a wider range of options, including various surface treatments like anodizing and powder coating. Additionally, their technical expertise should include in-house die design and development, ensuring they can create customized solutions tailored to your needs.

Customization is often a critical factor in choosing aluminum suppliers. A reliable supplier should offer flexibility in design and production to accommodate unique project specifications. This includes the ability to work with different aluminum alloys and provide various finishing options. Suppliers who offer design support can help optimize your products for manufacturing efficiency and cost-effectiveness, ultimately enhancing the final product's quality and performance.

Finally, consider the supplier's reliability and reputation within the industry. Research their track record for meeting delivery deadlines and maintaining consistent product quality. Customer testimonials and industry feedback can provide valuable insights into their service and reliability. A supplier with a strong reputation will not only meet your current needs but also support your long-term success by being a dependable partner in your supply chain.

In summary, selecting the right extruded aluminum supplier involves careful consideration of quality standards, production capabilities, customization options, and reliability. By focusing on these criteria, you can ensure that your projects benefit from high-quality materials and services, setting the stage for success in the competitive aluminum extrusion industry. As we move forward, we'll highlight some of the global leaders in aluminum extrusion who exemplify these qualities.

When it comes to selecting from the top aluminum extrusion companies, understanding the global landscape of suppliers is crucial. These companies not only set benchmarks for quality and innovation but also drive the industry forward with their advanced technologies and sustainable practices. Below, we present a table highlighting some of the leading global aluminum suppliers, including their headquarters and specializations.

| Company | Headquarters | Specialties |

|---|---|---|

| International Extrusions, Inc. | Garden City, Michigan, USA | Custom aluminum extrusions for various industries |

| PARCO, INC. | Fort Wayne, Indiana, USA | High-quality aluminum extrusions and fabrications |

| Minalex Corporation | Whitehouse Station, New Jersey, USA | Miniature custom aluminum extrusions |

| Shengxin Aluminum | Xuancheng, Anhui Province, China | Extensive range of aluminum profiles and innovative solutions |

| Bonnell Aluminum | Newnan, Georgia, USA | Custom aluminum extrusions and finishing services |

These global aluminum suppliers are recognized not only for their production capabilities but also for their commitment to innovation and sustainability. For instance, Shengxin Aluminum, as highlighted in the table, stands out for its comprehensive product range and dedication to quality and innovation. More details on Shengxin's offerings can be found in their official blog .

By considering these industry leaders, businesses can ensure they are partnering with suppliers who not only meet but exceed the rigorous demands of modern manufacturing. As we proceed, we will delve deeper into the specific attributes that make these companies stand out in the highly competitive field of aluminum extrusion.

In the realm of aluminum extrusion, few names resonate with the same level of excellence and innovation as Shengxin Aluminum. Established in 2003, Shengxin Aluminum has carved a niche for itself as a leader in the industry, renowned for its commitment to quality and a broad spectrum of aluminum profile solutions. But what truly sets Shengxin apart in this competitive landscape?

Shengxin Aluminum operates with an unwavering focus on quality, backed by certifications such as ISO9001 and ISO14001, which underscore their dedication to maintaining high standards across all production processes. This commitment is reflected in their sophisticated manufacturing capabilities, which include 43 extrusion lines ranging from 300 to 5500 tons, enabling them to produce a diverse array of profiles tailored to various industrial needs.

Innovation at Shengxin isn’t just a buzzword; it’s a core principle. Their state-of-the-art facilities span 350,000 square meters and house 28 advanced extrusion machines. This infrastructure supports the production of profiles with cross-sectional diameters up to 500 mm, catering to both standard and complex architectural applications. Moreover, Shengxin’s advanced CNC machining services ensure that each profile is not only precisely crafted but also ready for immediate application, saving their clients valuable time and resources.

Shengxin Aluminum offers a comprehensive range of aluminum extrusion profiles, from unit-type and frame-type eco-friendly curtain walls to high-tech industrial profiles used in refrigerated containers and new energy vehicles. Their product versatility is complemented by an array of surface finishing options like anodizing, powder coating, and wood grain treatments, enhancing both the durability and aesthetic appeal of their aluminum products.

Additionally, Shengxin’s expertise extends to providing tailored solutions through their dedicated mold workshop, which has developed thousands of custom molds for clients across over 100 countries. This ability to deliver bespoke designs ensures that they can meet the exact specifications of any project, no matter how unique.

With a strong presence in over 100 countries, Shengxin Aluminum is not just a local leader but a global player. Their reputation as a China Well-Known Trademark speaks to their reliability and exceptional service. Furthermore, Shengxin is committed to sustainability, with production processes designed to minimize waste and reduce environmental impact, aligning with global eco-friendly building solutions.

For more insights into their offerings and innovations, Shengxin Aluminum invites you to explore their official blog . By choosing Shengxin, businesses are assured of partnering with a supplier that prioritizes quality, innovation, and customer satisfaction, making them a quintessential choice in the aluminum extrusion industry.

In the competitive world of manufacturing, the ability to offer custom aluminum extrusion solutions can set a supplier apart. But why is customization so crucial, and how does it benefit your projects? Let's delve into the importance of tailored solutions in aluminum extrusion and explore how industry leaders like Shengxin Aluminum excel in this area.

Customization in aluminum extrusion allows for the creation of profiles that are precisely tailored to meet specific project requirements. This process involves designing unique shapes and features that enhance both functionality and aesthetics, which can be critical for sectors like construction, automotive, and electronics. By opting for custom solutions, companies can achieve greater design flexibility, which translates into innovative products that stand out in the market.

For instance, custom extrusions can incorporate specialized features such as channels, mounting points, and screw ports, simplifying assembly and reducing the need for additional components. This integration not only streamlines production processes but also enhances product performance by ensuring that every component fits perfectly within its intended application.

Effective design support in aluminum extrusion is another critical factor that suppliers must offer. This support involves collaborating closely with clients to develop detailed CAD designs and perform simulations that ensure precision and feasibility. Suppliers with robust design support capabilities can assist in optimizing designs for cost-effectiveness and manufacturability, ultimately leading to better quality and performance of the final product.

Shengxin Aluminum exemplifies excellence in this arena. With a comprehensive suite of design services, they work alongside clients to refine project specifications and develop custom molds that meet exacting standards. Their advanced CNC machining technology further ensures that each aluminum profile is crafted with precision, ready for immediate application.

Moreover, Shengxin's commitment to customization is reflected in their extensive range of finishing options, including anodizing, powder coating, and wood grain treatments, which enhance both the durability and visual appeal of their products. By offering such tailored solutions, Shengxin Aluminum not only meets the diverse needs of their clients but also helps them achieve a competitive edge in their respective industries.

In conclusion, the ability to provide custom aluminum extrusion and design support is indispensable for suppliers aiming to deliver high-quality, innovative products. As we look ahead, it's clear that choosing a supplier like Shengxin Aluminum, known for their expertise and commitment to customization, can significantly enhance your project's success and market impact.

When you think about sustainable aluminum suppliers, the commitment to eco-friendly practices often becomes a decisive factor in the selection process. As industries increasingly prioritize environmental responsibility, suppliers who adopt sustainable methods not only contribute to a healthier planet but also provide competitive advantages to their clients. But what makes a supplier truly sustainable, and how does this impact the aluminum extrusion industry?

Eco-friendly aluminum extrusion involves several key practices. First, the use of renewable energy sources, such as hydropower, significantly reduces the carbon footprint associated with aluminum production. According to the Aluminum Association, aluminum produced in North America today is less than half as carbon-intensive as it was three decades ago, thanks to these sustainable energy practices ( source ).

Moreover, sustainable suppliers focus on reducing waste through efficient production processes. This includes optimizing material usage and recycling scrap aluminum, which can be reprocessed without losing quality. Nearly 75% of all aluminum ever produced is still in use today, showcasing the metal’s recyclability and the industry's commitment to a circular economy.

Recycling initiatives are a cornerstone of eco-friendly aluminum extrusion. Suppliers implement comprehensive recycling programs to ensure that aluminum waste is minimized. This not only conserves natural resources but also reduces energy consumption, as recycling aluminum uses only 5% of the energy required to produce primary aluminum.

Leading companies in the industry are also exploring innovative technologies to further enhance sustainability. For example, advancements in alloy compositions and extrusion techniques allow for the creation of lighter, stronger materials that require less energy to produce and transport. These innovations contribute to the overall sustainability of aluminum products and their applications.

Shengxin Aluminum exemplifies the principles of sustainability in the aluminum extrusion industry. As a leader in eco-friendly aluminum extrusion, Shengxin employs advanced manufacturing processes that prioritize energy efficiency and waste reduction. Their commitment to sustainability extends to their product offerings, which include eco-friendly and energy-saving aluminum profiles for various applications.

Furthermore, Shengxin's dedication to sustainable practices is reflected in their use of renewable energy sources and their comprehensive recycling programs. By choosing Shengxin Aluminum, businesses can align with a supplier that not only meets their project needs but also supports their sustainability goals.

In conclusion, as the demand for sustainable solutions continues to grow, selecting an aluminum supplier with strong environmental credentials is more important than ever. By partnering with sustainable aluminum suppliers like Shengxin, companies can ensure that their projects contribute positively to the environment while benefiting from high-quality, eco-friendly products.

In the fast-paced world of manufacturing, staying ahead of the curve means embracing technological innovations. The aluminum extrusion industry is no exception, with recent advancements paving the way for increased efficiency and enhanced product capabilities. But what are these innovations, and how are they transforming the landscape of aluminum extrusion?

One of the most groundbreaking innovations in aluminum extrusion is the integration of 3D printing technologies. This hybrid approach combines the precision of extrusion with the versatility of additive manufacturing, allowing for the creation of complex, customized profiles that were previously challenging to produce. By utilizing 3D printing, manufacturers can quickly prototype and iterate designs, reducing lead times and enhancing product development cycles. This integration not only accelerates the design process but also opens up new possibilities for creating intricate geometries and lightweight structures tailored to specific applications.

Advancements in alloy compositions are another key area of innovation. Researchers and manufacturers are continuously developing new aluminum alloys that offer superior mechanical properties, such as increased strength, corrosion resistance, and thermal conductivity. For example, the introduction of high-strength alloys like the 7xxx and 8xxx series has expanded the range of applications for extruded aluminum, particularly in demanding sectors like aerospace and automotive. These advanced alloys enable the production of lighter and more durable components, which are crucial for improving fuel efficiency and performance in vehicles and aircraft.

The use of advanced simulation tools and automation technologies is revolutionizing the extrusion process. Sophisticated software allows manufacturers to model and optimize every aspect of extrusion, from die design to material flow and cooling profiles. This level of precision ensures that the final products meet exact specifications, reducing material waste and energy consumption. Additionally, automation technologies, including AI and IoT, are enhancing production efficiency by enabling real-time monitoring and predictive maintenance, minimizing downtime and maximizing throughput.

These advanced aluminum technologies are not just about improving efficiency; they also align with sustainability goals by reducing the environmental impact of manufacturing processes. As the industry continues to evolve, embracing these innovations will be essential for suppliers aiming to maintain a competitive edge and meet the growing demands for high-performance, eco-friendly aluminum products.

As we continue exploring the aluminum extrusion industry, we'll delve into how these technological advancements are being implemented by leading suppliers to drive growth and innovation.

As we've explored throughout this article, selecting the right extruded aluminum supplier is not merely a decision; it's a strategic move that can significantly impact the success of your projects. From understanding the intricacies of the aluminum extrusion process to recognizing the diverse applications across key industries, the importance of partnering with reputable aluminum suppliers cannot be overstated.

Choosing aluminum suppliers involves evaluating several critical factors. Quality standards and certifications ensure that the materials meet the necessary performance benchmarks. Production capabilities and technical expertise are crucial for handling complex designs and high-volume orders, while customization options allow for tailored solutions that align with specific project requirements. Moreover, the reliability and reputation of a supplier, as evidenced by their track record and customer feedback, provide assurance of consistent quality and timely delivery.

Reputable aluminum suppliers, such as Shengxin Aluminum, exemplify these qualities. Their commitment to quality, innovation, and sustainability makes them a standout choice in the industry. Shengxin Aluminum's extensive experience and diverse product offerings, including eco-friendly solutions, position them as a leader in the global market. By choosing such a supplier, you ensure that your projects benefit from high-quality materials and services, ultimately enhancing your competitive edge.

In conclusion, the importance of selecting the right supplier extends beyond immediate project needs. It encompasses long-term success, sustainability, and innovation. As you navigate the landscape of extruded aluminum suppliers, consider the insights shared in this article and prioritize partnerships with suppliers like Shengxin Aluminum, who demonstrate excellence and reliability in every aspect of their operations.

The top aluminum extrusion companies include global leaders like Shengxin Aluminum, known for their advanced manufacturing capabilities and commitment to innovation. Other notable companies are International Extrusions, Bonnell Aluminum, and Minalex Corporation, each offering specialized solutions across various industries.

Extruded aluminum is stronger and more durable than rolled aluminum due to its fabrication process, which uses more material to create robust shapes. This makes it ideal for applications requiring precision and strength, such as in automotive and aerospace industries.

The demand for aluminum extrusion is growing globally, driven by its versatility and strength. Industries like automotive, construction, and aerospace heavily rely on extruded aluminum for lightweight and durable solutions, contributing to a projected market growth rate of over 8% annually.

Customization in aluminum extrusion allows for tailored profiles that meet specific project needs, enhancing both functionality and aesthetics. It enables the creation of unique shapes and features, improving assembly efficiency and product performance, particularly in sectors like construction and electronics.

Sustainability in aluminum extrusion is crucial as it reduces environmental impact through recycling and energy-efficient practices. Companies like Shengxin Aluminum lead in eco-friendly manufacturing, ensuring their products contribute to a circular economy while maintaining high quality and performance standards.

Интернет Сервис

Интернет Сервис 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360