Anhui Aluminium Corporation: Shaping the Future of a Global Metals Market

Ever wondered how a single region can become a powerhouse in a global industry? When you look at the Anhui aluminium corporation and the broader Anhui aluminium industry, you’ll notice a remarkable story of growth, innovation, and strategic advantage that sets this region apart as a pivotal hub for aluminum production in China—and the world.

Why does Anhui matter so much in the aluminum landscape? The answer starts with its unique blend of historical development, abundant resources, and a prime geographic location. Let’s break down how Anhui’s aluminum sector evolved and why it stands out today:

-

Strategic Location: Anhui sits at the crossroads of eastern China, with access to major transportation networks, making it an ideal site for both domestic distribution and international export.

-

Resource Availability: The province benefits from proximity to bauxite resources and a robust supply chain, ensuring a steady flow of raw materials for processing into aluminum products.

-

Industrial Policy Support: Forward-thinking government policies have encouraged investment in advanced manufacturing, sustainability, and technological innovation, helping local enterprises scale up rapidly.

Historically, Anhui’s journey in the aluminum sector began with small-scale enterprises focused on basic processing. Over the decades, this landscape transformed dramatically. By the 1990s, companies like Shengxin Aluminium Corporation were established, bringing modern production lines and large-scale operations to the region. By leveraging state-of-the-art technologies and adhering to international standards, these enterprises have helped Anhui evolve from a regional supplier to a key player in the global aluminum market.

Today, the Anhui aluminium corporation represents not just a single entity but a collective force of manufacturers, research institutions, and policy-makers. The region’s industry covers the entire value chain—from raw material extraction and recycling to high-end product fabrication and export. This integrated approach allows Anhui to respond quickly to market changes, innovate new products, and meet the diverse needs of industries ranging from construction and automotive to electronics and renewable energy.

Imagine a network of world-class production facilities, advanced recycling operations, and cutting-edge R&D centers—this is the reality of the Anhui aluminium industry. The province’s ability to combine scale, efficiency, and sustainability has positioned it as a central hub for aluminum production, shaping not only the future of China’s metals market but also influencing trends across the globe.

When you think about aluminum production in Anhui, you might picture massive factories, intricate machinery, and a seamless supply chain that stretches from recycled scrap to high-end finished goods. Sounds complex? Let’s break it down to see how this province has become a powerhouse for both raw material processing and value-added manufacturing.

From Raw Materials to Finished Products: A Complete Value Chain

Aluminum production in Anhui is more than just smelting metal—it’s about creating an ecosystem. The province boasts a comprehensive industry chain that covers:

-

Primary Aluminum Processing: The transformation of raw bauxite and recycled materials into aluminum ingots and alloys.

-

Advanced Alloy Manufacturing: Production of specialized aluminum-magnesium alloys, high-strength structural components, and liquid aluminum alloys for industrial use.

-

Deep Processing and Fabrication: Extrusion, rolling, coating, and machining to create profiles, sheets, coils, and composite panels.

-

Recycling and Sustainability: Integrated recycling operations that turn scrap aluminum into high-quality secondary products, supporting circular economy goals (source).

What makes Anhui stand out? It’s the presence of well-established manufacturers and carefully developed industrial parks:

-

Anhui Shengxin New Materials Co., Ltd.: The largest aluminum profile manufacturer in the province, with over 100 production lines for casting, extrusion, anodizing, powder coating, and more. Shengxin’s annual capacity reaches 100,000 tons, serving markets from rail transit to energy-saving construction.

-

Anhui Yishengyuan New Materials Co., Ltd.: Specializes in aluminum alloy ingots and aluminum-magnesium alloys, with a focus on automotive supply chains and advanced environmental protection equipment. Annual output is 200,000 metric tons, and the company is a leader in recycling and resource efficiency (source).

-

Anhui Wonderful-Wall Science Technology Corp., Ltd.: The region’s top producer of prepainted aluminum coils, solid sheets, and composite panels. With a capacity for 100,000 MT of prepainted aluminum coil annually, the company supplies both domestic and international construction, decoration, and energy markets.

These companies are often clustered in economic development zones—such as Xuancheng and Qingyang County—which offer streamlined logistics, shared R&D resources, and access to skilled labor. This clustering accelerates innovation and ensures that Anhui aluminum manufacturers remain competitive on a global scale.

Product Diversity and Applications

So, what exactly does Anhui produce? The product range is remarkably broad, supporting a wide variety of industries. Here’s a snapshot:

-

Aluminum Profiles: For windows, doors, curtain walls, and industrial frameworks (used in construction, rail transit, and new energy vehicles).

-

Aluminum Alloy Ingots & Liquid Alloys: Essential for automotive parts, machinery, and electronics.

-

Prepainted Coils & Sheets: Used in architectural cladding, roofing, signage, and decorative panels.

-

Composite Panels: For energy-saving building materials and insulation systems.

-

Recycled Aluminum Products: Feeding back into auto, packaging, and consumer goods sectors.

As you explore further, you’ll see how these diverse products and integrated operations set the stage for Anhui’s leading role in the next chapter—profiling the key players and their specializations within this dynamic industry.

When you think about the scale and diversity of the Anhui aluminium corporation landscape, you might wonder: Who are the leading aluminum companies in Anhui, and what sets them apart? Let’s break down the key players, their areas of expertise, and how their collaborative efforts drive innovation and industrial growth across the province.

Spotlight on Major Aluminum Enterprises

Across Anhui, several enterprises anchor the regional aluminum industry. Their operations range from primary aluminum production to recycling and the development of high-performance alloys. Here’s what makes these companies stand out:

-

Primary Aluminum Production: Companies in this segment focus on transforming raw bauxite and recycled materials into high-purity aluminum ingots and billets, which serve as the foundation for downstream processing.

-

Recycled and Secondary Aluminum: With a growing commitment to sustainability, many Anhui manufacturers have invested in recycling facilities, converting scrap and industrial waste into valuable secondary aluminum products.

-

Specialized Alloys and Deep Processing: Some enterprises specialize in producing advanced aluminum-magnesium alloys, high-strength extrusions, and components tailored for automotive, rail transit, and new energy applications.

Shengxin Aluminum: A Leading Force in Anhui

Imagine a company that not only leads in production capacity but also sets benchmarks for quality and innovation. That’s the story of Shengxin Aluminum, the largest aluminum profiles manufacturer in Anhui Province. Here’s why Shengxin stands out among Anhui aluminium corporation locations:

-

Scale and Capacity: With more than 100 production lines—including fusion casting, extrusion, anodizing, powder coating, and thermal break processes—Shengxin boasts an annual production capacity of 100,000 tons of aluminum profiles. The company operates the largest extrusion line in the province, handling up to 5,500 tons.

-

Product Diversity: Shengxin produces a wide array of aluminum profiles, from energy-saving curtain wall and window systems to high-tech industrial profiles for refrigerated containers, rail transit, and new energy vehicles. Their products are integral to major infrastructure projects, including over 30 subway lines across China.

-

Technological Excellence: The company collaborates with Hefei Industrial University as a Practice Teaching Base, integrating research-driven innovation into its manufacturing processes. Shengxin’s technical team includes some of China’s top engineers, and its products have earned the recognition of a China Well-Known Trademark (source).

-

Comprehensive Processing Capabilities: From 43 extrusion lines (ranging from 300 to 5,500 tons) to multiple powder coating, anodizing, and wood grain lines, Shengxin’s facilities support deep processing, including advanced CNC machining for custom applications.

Collaboration and Innovation Across the Sector

What truly sets Anhui’s aluminum sector apart is the spirit of collaboration—between enterprises, research institutes, and local government. Companies like Shengxin leverage their relationships with universities and technical institutes to pioneer new materials and processing methods. This synergy accelerates the adoption of advanced technologies, such as high-precision extrusion, automated surface finishing, and eco-friendly coatings.

Other leading aluminum companies in Anhui, though not detailed here, follow similar paths—combining robust industrial infrastructure with a focus on sustainability and continuous improvement. Many are clustered in economic and technological development zones, which offer shared resources and foster a dynamic environment for cross-sector partnerships.

As you explore the next chapter, you’ll see how these technological capabilities and innovative practices are transforming the aluminum industry in Anhui, setting new standards for efficiency, quality, and environmental responsibility.

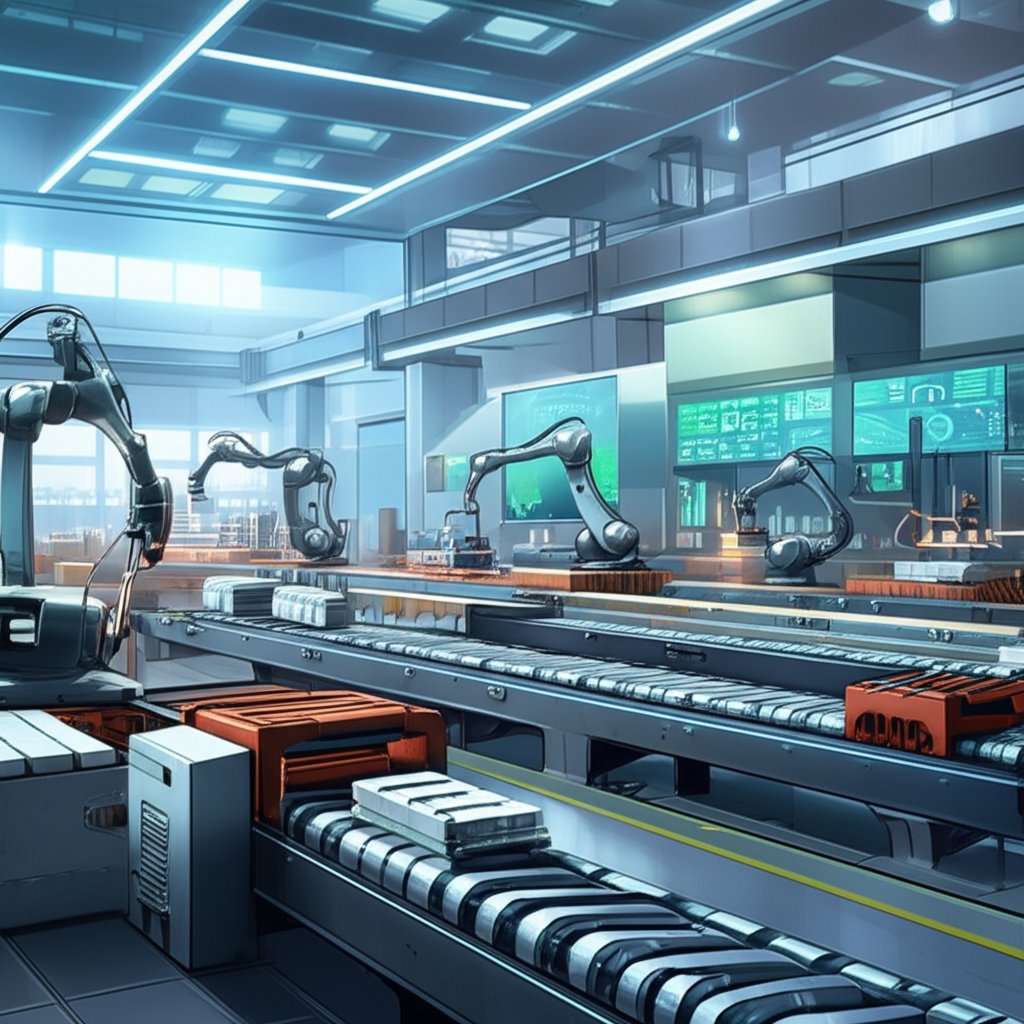

When you hear about aluminum processing innovation, you might wonder: What makes Anhui’s aluminum sector a leader in both technology and sustainability? Imagine walking through a modern factory floor in Anhui—automated lines, gleaming aluminum billets, and a distinct focus on eco-friendly practices. Let’s break down how these advancements are reshaping the region’s aluminum industry and setting new benchmarks for sustainable aluminum production.

Next-Generation Processing: From Casting to CNC Machining

Aluminum manufacturing in Anhui has evolved far beyond basic smelting. Here, advanced production processes are the norm, enabling manufacturers to deliver high-quality, precision-engineered products for industries as diverse as automotive, construction, and renewable energy. Key processes include:

-

Precision Casting: Facilities like Anhui Jiasheng Metal Technology Co., Ltd. use state-of-the-art melting and refining furnaces, online degassing, and two-stage filtration to ensure the purity and consistency of aluminum billets. Their billet production lines can handle a wide range of sizes and alloy grades, supporting everything from electric vehicle battery trays to high-speed rail components (source).

-

Extrusion Technology: The region is recognized for its extensive use of aluminum extrusion, a process that shapes aluminum under high pressure through custom dies. This method allows for the creation of complex profiles with excellent surface finishes—ideal for windows, doors, and lightweight automotive parts (source).

-

Anodizing and Powder Coating: Surface treatments like anodizing and powder coating not only enhance appearance but also improve corrosion resistance and durability. Anhui’s leading producers offer both vertical and horizontal powder coating lines, as well as multiple anodizing lines for custom finishes.

-

CNC Machining: Deep processing workshops are equipped with advanced CNC machines—some capable of handling parts up to 8 meters long. This enables high-precision manufacturing for critical applications in rail transit and industrial automation.

Green Technologies and Sustainable Aluminum Production

But innovation in Anhui isn’t just about speed and precision—it’s also about responsibility. As global demand for low-carbon materials grows, local enterprises are pioneering sustainable aluminum production at every stage:

-

Closed-Loop Recycling: Companies like Anhui Bolan New Material Technology Co., Ltd. have established comprehensive recycling systems that convert aluminum scrap into high-end billets and ingots. Their intelligent “1+1+3” furnace configuration and advanced sorting processes ensure 100% clean production, maximizing resource efficiency (source).

-

Energy-Efficient Furnaces: The adoption of double-chamber melting furnaces and tilting alloy furnaces reduces energy consumption and emissions, supporting China’s ambitious carbon neutrality goals.

-

Smart Manufacturing: Integration of intelligent control systems and real-time monitoring helps optimize energy use, minimize waste, and ensure consistent product quality across large-scale operations.

-

Collaborative Innovation: By working closely with research institutions and industry alliances, Anhui’s aluminum sector accelerates the adoption of new green technologies and best practices throughout the supply chain.

Comparing Traditional and Innovative Aluminum Processing Techniques

So, how do these advancements stack up against older methods? The table below highlights key differences in efficiency, cost-effectiveness, and environmental impact:

|

Processing Method

|

Efficiency

|

Cost-Effectiveness

|

Environmental Impact

|

|

Traditional Casting (Sand/Mold/Die Casting)

|

Moderate (batch production, longer cooling times)

|

Good for high volumes, but higher material waste

|

Higher energy use, more emissions, limited recycling

|

|

Modern Extrusion & CNC Machining

|

High (continuous, automated, precise)

|

Flexible for custom shapes, less waste, scalable

|

Lower emissions, supports recycled content, cleaner processes

|

|

Green Secondary Aluminum Production

|

Very High (closed-loop, rapid throughput)

|

Highly cost-effective, maximizes scrap value

|

Minimal emissions, circular economy, resource-efficient

|

Shengxin Aluminum: Benchmarking Excellence in Process Innovation

Leading enterprises such as Shengxin Aluminum exemplify Anhui’s commitment to technological excellence. With over 100 production lines—including 43 extrusion lines, multiple powder coating and anodizing lines, and advanced deep processing workshops—Shengxin integrates process innovation and sustainability at every step. Their products power major infrastructure projects, new energy vehicles, and smart buildings, reinforcing Anhui’s position as a global hub for advanced aluminum manufacturing.

As you look ahead, you’ll see how these technological breakthroughs and sustainable practices are not only transforming the local economy but also expanding Anhui’s reach into new international markets and high-value industries.

When you consider the scale of the Anhui aluminum industry, you might ask: How does this sector shape the local economy—and how far does its influence reach? The answers reveal a story of robust economic contribution, job creation, and a global footprint that connects Anhui’s aluminum to industries and markets around the world.

Anhui’s Aluminum Industry: Driving Economic Growth

Let’s start with the big picture. The aluminum sector in Anhui is a cornerstone of the province’s industrial economy. Through a combination of primary production, advanced processing, and recycling, this industry:

-

Provides substantial employment: Major enterprises like Mingkun Aluminum employ hundreds, with the broader supply chain supporting thousands more in manufacturing, logistics, and research (source).

-

Boosts regional GDP: The value-added from aluminum production, deep processing, and export activities makes a significant contribution to Anhui’s GDP, helping to drive modernization and infrastructure development.

-

Spurs investment: Ongoing expansion in production lines, recycling facilities, and technology upgrades attracts both domestic and foreign capital, strengthening the province’s industrial base.

Export Volumes and Global Reach

Imagine Anhui’s aluminum products traveling from local factories to construction sites, car plants, and high-tech facilities across the globe. In recent years, China’s aluminum exports have reached record highs, with the first 11 months alone seeing 5.83 million tons exported nationally—a 20.8% year-on-year increase. Anhui, as a key production hub, plays a vital role in this surge, especially in high-demand categories like aluminum plates, foils, and extrusions. For example:

-

Aluminum Plates: 3.16 million tons exported nationally, up 25% year-on-year.

-

Aluminum Foils: 1.44 million tons, up 19.7%.

-

Aluminum Extrusions: 1.15 million tons, up 12.1% (source).

While export conditions have grown more complex due to global trade tensions and policy shifts, the resilience and adaptability of Anhui’s aluminum sector ensure steady growth and continued international relevance.

Key Export Markets for Anhui Aluminum

So, where do Anhui’s aluminum products go? The province’s manufacturers serve a diverse range of Anhui aluminum export markets, including:

-

Asia: Key destinations such as Japan, South Korea, Thailand, and Vietnam.

-

Europe: Germany, Italy, and Eastern European countries for automotive and industrial components.

-

North America: The United States and Mexico, especially for construction and packaging materials.

-

Emerging Markets: India, the Middle East, and Africa, where demand for construction and infrastructure materials is rising.

Despite recent challenges—like increased tariffs and anti-dumping investigations—the sector continues to adjust strategies, shifting to higher-value products and strengthening relationships with global partners.

Industries Using Anhui Aluminum: A Broad Spectrum of Applications

It’s not just about where the aluminum goes, but how it’s used. Anhui’s aluminum products are essential to a wide range of industries, supporting everything from urban skylines to cutting-edge technology. Here’s a breakdown of industries using Anhui aluminum and their connections to the province’s supply chain:

-

Construction & Architecture: Aluminum profiles, panels, and extrusions for windows, doors, curtain walls, and energy-efficient buildings.

-

Automotive & Transportation: Lightweight components for new energy vehicles, rail transit, and logistics equipment.

-

Packaging: Aluminum foil and sheets for food, pharmaceuticals, and consumer goods packaging.

-

Electronics & Appliances: High-precision extrusions and parts for electronics, home appliances, and industrial automation.

-

Renewable Energy: Aluminum frames and components for solar photovoltaic panels, battery foils, and energy storage systems.

-

Medical & Environmental Protection: Specialized profiles and assemblies for medical devices and eco-friendly infrastructure (source).

"Anhui’s aluminum industry is not just a driver of local prosperity—it’s a vital link in global supply chains, powering the growth of diverse sectors from green energy to smart infrastructure."

As you move forward, you’ll see how the economic impact and global reach of Anhui’s aluminum sector set the stage for navigating new challenges and seizing opportunities in this dynamic industry.

When you hear about the impressive growth of the Anhui aluminium industry, you might wonder: What hurdles do these companies face—and how do they turn obstacles into opportunities? Let’s break down the key challenges in Anhui aluminum industry today, and explore the innovative ways leading enterprises are adapting to a rapidly changing market.

Major Challenges Facing Anhui’s Aluminum Industry

Imagine running a high-tech aluminum factory in Anhui. One day, global bauxite prices spike. The next, new tariffs hit your exports. Sound familiar? These are just a few of the real-world challenges confronting aluminum producers in the province:

-

Raw Material Price Volatility: The cost of bauxite and energy—both essential for aluminum production—fluctuates due to global commodity trends, geopolitical tensions, and supply chain disruptions. This volatility squeezes profit margins and makes long-term planning difficult for manufacturers (source).

-

Trade Frictions and Policy Shifts: International trade tensions, tariffs, and anti-dumping investigations have increased the complexity of exporting aluminum products. Companies must constantly adapt to new regulations and navigate shifting market access conditions.

-

Stringent Environmental Regulations: As China pursues ambitious carbon neutrality goals, Anhui’s aluminum producers face tougher standards for emissions, waste management, and energy efficiency. Compliance requires significant investment in green technologies and process upgrades (source).

-

Supply Chain Disruptions: Global events, from pandemics to logistics bottlenecks, can delay shipments and impact the steady flow of raw materials and finished goods.

-

Labor and Skills Gap: As the industry adopts more automation and smart manufacturing, there’s a growing need for highly skilled workers to operate advanced machinery and manage digital systems.

Adapting to Global Dynamics: How Anhui’s Aluminum Sector Responds

Despite these challenges, Anhui’s aluminum enterprises are anything but passive. Here’s how the industry is adapting to global market dynamics and policy changes:

-

Investing in Energy Efficiency: Many factories are upgrading to energy-saving furnaces, optimizing process parameters, and recovering waste heat to cut costs and reduce emissions.

-

Strengthening Quality Control: Rigorous inspection systems and advanced testing (like X-ray and ultrasonic analysis) ensure consistent product quality and help meet international standards (source).

-

Diversifying Supply Chains: To manage raw material risks, companies are forming new partnerships and exploring alternative sourcing strategies, both domestically and abroad.

-

Embracing Automation and Smart Manufacturing: By integrating AI, robotics, and digital monitoring, manufacturers can boost productivity, minimize errors, and adapt quickly to market changes.

Opportunities for Anhui Aluminium Corporation: High-Value Products and Sustainable Growth

Every challenge brings new opportunities for Anhui aluminium corporation and its peers. Here’s where the industry sees the greatest potential:

-

Emerging Markets: As demand for lightweight, durable materials grows in Southeast Asia, Africa, and the Middle East, Anhui’s aluminum products are finding new customers in infrastructure, automotive, and renewable energy sectors.

-

High-Value-Added Products: Moving beyond commodity exports, manufacturers are focusing on advanced alloys, precision extrusions, and customized profiles for electric vehicles, rail transit, and smart construction.

-

Sustainable Aluminum: The shift to recycled and secondary aluminum is accelerating. Companies like Anhui Kaifei New Material Technology Co., Ltd. have invested in closed-loop recycling and digitalized production, cutting energy use and emissions by over 50% (source).

-

Green Manufacturing: Adoption of eco-friendly practices—such as intelligent sorting, automated smelting, and real-time emissions monitoring—helps companies meet regulatory requirements and appeal to global customers seeking sustainable suppliers.

Case Study: Shengxin Aluminum’s Innovative Approach

Wondering how industry leaders turn strategy into action? Take Shengxin Aluminum as an example. As the largest aluminum profiles manufacturer in Anhui, Shengxin has embraced both technological and environmental innovation:

-

Advanced Production Lines: With more than 100 lines, including 43 for extrusion and several for powder coating and anodizing, Shengxin integrates automation, precision, and flexibility to meet diverse market needs.

-

Green Initiatives: The company’s investment in energy-efficient equipment, waste reduction, and closed-loop recycling supports both cost savings and compliance with China’s carbon neutrality goals.

-

Collaboration for Innovation: Shengxin partners with research universities to develop new materials and processes, ensuring it stays ahead of regulatory and market trends.

-

Diversified Product Portfolio: From customized rail transit profiles to eco-friendly building systems, Shengxin’s high-value products are designed for future growth sectors.

As you look toward the future, you’ll see how these adaptive strategies and innovative practices position Anhui’s aluminum sector to thrive—transforming challenges into opportunities for sustainable, global growth.

What will the future of Anhui aluminium industry look like in a rapidly changing world? Imagine a landscape where digital factories hum with automation, recycled aluminum flows seamlessly back into high-value products, and every innovation supports a greener tomorrow. As you look ahead, several powerful trends and government initiatives are shaping Anhui’s aluminum sector into a model for smart, sustainable manufacturing.

Government Vision: High-Quality Development and Green Transformation

China’s national and provincial governments are driving the future of Anhui aluminium industry through ambitious policies and investments. The Action Plan for the High-Quality Development of the Aluminium Industry (2025–2027) sets a strategic course for the next decade. Here’s how these plans are transforming the landscape:

-

Resource Security and Circular Economy: New policies require aluminum projects to match bauxite mining rights with processing capacity and prioritize red mud utilization, reinforcing local resource security and environmental responsibility.

-

Capacity and Environmental Controls: Strict approval standards for new or expanded facilities ensure that only the most energy-efficient and environmentally friendly operations move forward. This means energy use is capped, emissions are minimized, and new capacity is encouraged in clean energy-rich regions.

-

Recycled Aluminum Targets: The government aims for a 15 million ton annual recycled aluminum target, highlighting the growing importance of secondary aluminum and closed-loop recycling in Anhui’s future industrial mix.

Smart Manufacturing: Digitalization and Automation Take Center Stage

Ever wondered how a factory can go from hours-long processes to split-second decisions? In Anhui, smart manufacturing is quickly becoming the norm. Over 80% of large industrial enterprises in the province have begun digital transformation, with more than half achieving full digital integration (source). Here’s what you’ll notice as Anhui aluminum smart manufacturing takes off:

-

Intelligent Production Lines: Automation, real-time data monitoring, and AI-driven quality control boost efficiency and reduce waste.

-

Lighthouse Factories: Anhui is home to several World Economic Forum–recognized “lighthouse” factories, which set global benchmarks for digitalization and operational excellence.

-

Virtual Industrial Engineers: Advanced software can now optimize processes in seconds, enabling rapid shifts in production and continuous improvement.

Green Innovation: Leading the Circular Economy

As sustainability becomes a defining factor in global metals markets, Anhui’s aluminum sector is embracing the circular economy at every stage. Imagine a future where:

-

Aluminum scrap is efficiently collected, sorted, and transformed into high-end billets and extrusions for new applications.

-

Energy-efficient furnaces and clean energy sources dramatically lower the carbon footprint of every ton produced.

-

Industrial parks operate as closed-loop ecosystems, where waste from one process becomes input for another, maximizing resource use and minimizing environmental impact (source).

Emerging Applications: New Energy Vehicles and Photovoltaics

What industries will drive demand for Anhui aluminum in the coming years? The answer lies in high-growth sectors like new energy vehicles (NEVs) and solar photovoltaics (PV):

-

NEVs: Lightweight aluminum extrusions are critical for battery trays, chassis systems, and crash management components in electric vehicles. As China and the world accelerate EV adoption, Anhui’s advanced extrusion capabilities will be in high demand.

-

Photovoltaics: Solar panel frames and mounting systems rely on precision aluminum components. With the global shift towards renewable energy, Anhui’s aluminum products will play a pivotal role in supporting clean power infrastructure.

Future Goals and Expectations

Looking forward, Anhui’s aluminum sector is poised to achieve several key objectives:

-

Strengthen integration between upstream resource supply and downstream processing for greater efficiency.

-

Expand the use of digital and smart technologies across all production stages, setting new industry benchmarks.

-

Lead China’s transition to a circular economy, with recycled aluminum and green manufacturing as core drivers.

-

Capture new markets in NEVs, PV, and high-value industrial applications by focusing on innovation and quality.

"Anhui’s aluminum industry is not only keeping pace with global trends—it’s helping define them, blending smart manufacturing, sustainability, and industrial innovation to shape the future of metals worldwide."

As you reflect on these future trends, it’s clear that Anhui’s aluminum sector stands at the forefront of a new era—one where technology, green practices, and global vision converge to create lasting value for industries and communities alike.

When you step back and look at the journey of the Anhui aluminium corporation and its peers, you’ll notice a story that’s not just about metal, but about vision, innovation, and enduring value. What are the real Anhui aluminum industry strengths, and why does this region matter so much in the global aluminum supply chain?

Key Strengths of Anhui’s Aluminum Industry

-

Robust Production Capacity: Anhui’s manufacturers, led by top enterprises like Shengxin Aluminum, operate more than 100 production lines, supporting an annual output that reaches into the hundreds of thousands of tons. This scale ensures a stable, reliable supply for both domestic and international markets (source).

-

Technological Innovation: Imagine a factory floor where automation, precision CNC machining, and advanced surface treatments are standard. Anhui’s aluminum sector invests heavily in R&D, collaborating with local universities and research institutes to drive continuous improvement and stay ahead of industry trends.

-

Economic Contribution: The industry is a cornerstone of Anhui’s economy, creating thousands of jobs, boosting local GDP, and attracting investment from both China and abroad. Its export reach is global, with products shipped to North America, Europe, Asia, and emerging markets.

-

Sustainability and Circular Economy: With a strong focus on recycling and green manufacturing, Anhui’s aluminum producers are leaders in secondary aluminum and resource efficiency. Closed-loop recycling systems and energy-efficient processes are helping the region meet ambitious environmental goals (source).

-

Product Diversity and Market Adaptability: From household foil and kitchenware to high-tech extrusions for new energy vehicles and solar panels, the range of products is vast. This flexibility helps Anhui’s aluminum sector respond quickly to changing global demands.

Anhui’s Role in the Global Aluminum Supply Chain

Think about the flow of aluminum from a smelter in Anhui to a skyscraper in Europe or an electric vehicle assembly line in North America. Anhui aluminium corporation global supply is not just a phrase—it’s a reality. With 508 shipments and over $22 million in trade value across dozens of international partners in just three years, Anhui’s aluminum products are integral to worldwide supply chains (source).

Leading enterprises like Shengxin Aluminum exemplify the region’s excellence. With deep capabilities in extrusion, coating, anodizing, and custom fabrication, Shengxin’s products are found in everything from energy-saving buildings to high-speed rail systems. Their commitment to quality, innovation, and sustainability sets a benchmark not just for Anhui, but for the global industry.

Looking Ahead: Why Anhui is a Hub of Innovation and Reliability

-

Continued investment in smart manufacturing and digitalization will enable even greater efficiency and product quality.

-

Green initiatives and closed-loop recycling will keep Anhui at the forefront of sustainable metals production.

-

Strong partnerships with research institutions and global customers will ensure that Anhui’s aluminum industry remains agile and future-ready.

"As the world demands smarter, greener, and more reliable materials, Anhui’s aluminum sector stands ready—shaping the future of a global metals market and earning its place as a trusted partner in every major supply chain."

1. What makes Anhui Aluminium Corporation a leader in China's aluminum industry?

Anhui Aluminium Corporation stands out due to its extensive production capacity, advanced technology, and commitment to sustainability. The corporation integrates the full aluminum value chain, from raw material processing to high-end product manufacturing. Strategic location, strong policy support, and collaboration with research institutions further strengthen its position as a leading force in China's and the global aluminum market.

2. Which industries rely most on aluminum products from Anhui?

A wide range of industries depend on Anhui's aluminum products, including construction, automotive and transportation, packaging, electronics and appliances, renewable energy, and medical equipment. These sectors benefit from Anhui's diverse product offerings, such as extrusions, alloy ingots, foils, and components that support energy efficiency and technological advancement.

3. How does Anhui Aluminium Corporation address environmental sustainability?

The corporation prioritizes green manufacturing by investing in energy-efficient furnaces, closed-loop recycling systems, and advanced waste management. Many facilities use intelligent automation and real-time monitoring to minimize emissions and resource use. This commitment helps Anhui meet strict environmental regulations and global sustainability standards.

4. What technological innovations set Anhui's aluminum sector apart?

Anhui's aluminum industry leads in process innovation, including precision casting, automated extrusion, advanced surface treatments like anodizing and powder coating, and high-precision CNC machining. The adoption of smart manufacturing and digitalization enhances product quality, efficiency, and adaptability to market demands.

5. Who is Shengxin Aluminum and what role do they play in Anhui's industry?

Shengxin Aluminum is the largest aluminum profile manufacturer in Anhui Province, known for its extensive production lines and high-quality products. As a high-tech enterprise, Shengxin collaborates with universities, invests in advanced equipment, and serves markets such as rail transit, construction, and new energy vehicles, exemplifying Anhui's industrial excellence.

Интернет Сервис

Интернет Сервис 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360