Have you ever paused to consider just how much aluminum shapes your daily life? From the soda can in your hand to the sleek body of an airplane overhead, aluminum is everywhere. Its unique blend of lightweight strength, corrosion resistance, and recyclability makes it a go-to material for industries as diverse as construction, transportation, packaging, and electronics. In fact, it’s nearly impossible to list all the ways aluminum impacts our world—think buildings, cars, smartphones, kitchen appliances, and so much more.

But why should you care about the aluminum price per lb? Imagine you’re a contractor planning your next big project, a manufacturer sourcing raw materials, or even a recycling enthusiast hoping to maximize your returns. In each scenario, the price you pay—or receive—for aluminum can make a significant difference to your bottom line. The aluminum price per pound chart isn’t just a number; it’s a pulse on global economics, supply chains, and even environmental progress.

Given this widespread use, fluctuations in aluminum pricing ripple through countless products and industries. That’s why understanding what drives the price per pound is essential for both big businesses and everyday consumers.

Sounds complex? It can be. But this guide is designed to make sense of it all. Here’s what you’ll learn:

By the end of this article, you’ll have a clear understanding of how the aluminum market works, what shapes its price per pound, and how to use this knowledge to your advantage—no matter your role in the aluminum value chain.

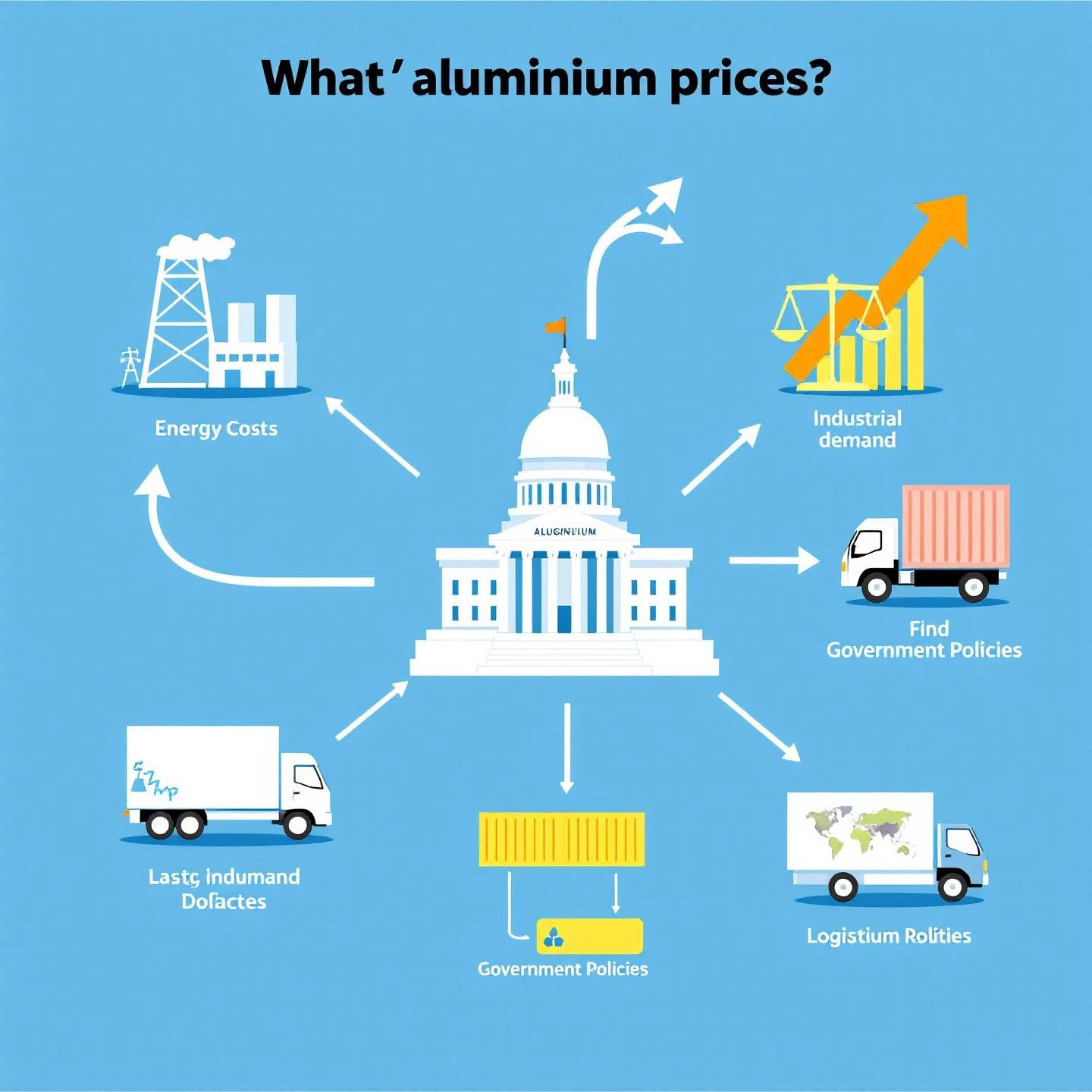

Ever wondered why the global aluminum price seems to shift as unpredictably as the weather? One day, prices are steady; the next, they jump or dip with little warning. If you’ve ever tried to budget for a construction project, run a manufacturing line, or even recycle cans, you’ve likely felt the impact of these swings. The truth is, factors affecting aluminum price are numerous and deeply interconnected—making the market both fascinating and challenging to navigate.

Let’s break down the main drivers behind aluminum’s price per pound. Think of these as the gears in a complex machine: when one moves, the rest often follow.

Imagine the aluminum market as a global dance—when one partner stumbles, everyone feels it. A labor strike in Guinea, a new environmental law in China, or a surge in electric vehicle sales in Europe can all change the rhythm. Even global events like pandemics or geopolitical tensions can send prices swinging dramatically, as seen in recent years.

For anyone tracking the aluminum price per lb, it’s crucial to watch not just one factor, but the entire ecosystem. By understanding these drivers, you’ll be better prepared to anticipate price changes and make smarter decisions—whether you’re buying, selling, or simply keeping an eye on the market.

Next, we’ll explore how to find and interpret the current spot price of aluminum, so you can act on these insights in real time.

Ever tried to check the current aluminum price per lb and found yourself lost in a maze of charts and numbers? If you’re buying raw material for a project or selling scrap, knowing the real-time price can make a big difference to your bottom line. But what exactly is the aluminum spot price, and how can you use it to your advantage?

Let’s break it down: the spot price is the price at which aluminum can be bought or sold for immediate delivery in a specific market. Think of it as the “right now” price—the amount you’d pay (or receive) if you made a transaction today, rather than agreeing to buy or sell at a future date. This is different from a futures price, which is set for delivery at a later time and often used by manufacturers and traders to hedge against price changes down the road.

Why does this distinction matter? Imagine you’re a scrap seller hoping to maximize your payout. The spot price tells you what you can get if you deliver your aluminum today. If you’re a manufacturer, futures prices help you plan your costs weeks or months in advance, but the spot price still anchors what’s happening in the market right now.

With so much information online, how do you know which sources to trust? Here are some practical ways to track the current aluminum price per lb:

Reading spot price charts isn’t just for traders. Here’s how you can make sense of the data for your needs:

"The spot price is your most accurate window into the real-time value of aluminum—but it’s only one part of the equation. Always consider additional costs and local market factors before making a decision."

Now that you know how to find and interpret the spot price, you’re in a better position to make informed choices—whether you’re buying for a business or selling scrap from your garage. Next, we’ll look at how scrap aluminum is graded and why it matters for your payout.

Ever wondered why two piles of aluminum scrap can fetch such different prices at the yard? Or why your neighbor’s soda cans seem to earn less per pound than that stack of window frames you’re about to haul in? The answer lies in the way scrap aluminum is graded—and these grades play a huge role in determining the scrap aluminum price per lb you’ll receive.

When you bring aluminum to a scrap yard, it’s not just about weight. It’s about quality. The purer and cleaner your aluminum, the more it’s worth. But what does “clean” actually mean in the world of recycling?

You’ll notice that even a small amount of contamination can drop your payout significantly. Imagine the difference between a shiny, stripped bicycle frame and a grill caked with grease and bolts—the cleaner piece is always more valuable.

Scrap yards sort aluminum by both physical form and alloy content. Here’s a breakdown of the most common grades you’ll encounter, along with their characteristics and average values, based on recent market pricing (Reliable Recycling Center):

| Type/Grade | Typical Examples | Key Characteristics | Average Price per lb* |

|---|---|---|---|

| UBC (Used Beverage Cans) | Soda, beer, and food cans (clean, no foil or pet food cans) | Lightweight, easily compacted, must be free of residue for best price |

$0.45 (under 100 lbs) $0.48 (over 100 lbs) |

| Clean Sheet Aluminum | Window frames (without plastic), lawn chairs (no webbing), pots/pans | No attachments, minimal paint, not cast or extruded | $0.50 |

| Painted Siding | Aluminum house siding, gutters (clean, no plastic or steel) | May have paint but must be free of non-aluminum | $0.53–$0.55 |

| Cast Aluminum | BBQ grills, engine parts, light pole bases | Thicker, poured into molds, may have minor contamination | $0.50 |

| Extruded Aluminum | Window/door frames, bicycle parts (no plastic/steel attached) | Long, uniform cross-section, clean of attachments | $0.70 |

| Dirty Aluminum | Anything with steel, plastic, or rubber attached | Requires extra processing, lower value | Varies (often $0.15–$0.30) |

*Prices are indicative and may vary by region and scrap yard. Always check your local rates before selling.

"The cleaner and better sorted your aluminum, the higher the price per pound you’ll command."

Understanding how scrap aluminum is graded empowers you to make smarter decisions—whether you’re cleaning out your garage, running a contracting business, or recycling for extra income. Next, we’ll share practical strategies to help you maximize your payout when selling aluminum cans specifically.

When you’re ready to turn your empty cans into extra cash, a little know-how can make a big difference in your payout. Ever wondered why some people seem to earn more for their cans, or how to make your recycling trips truly worth the effort? Let’s break down the proven steps to help you get the best aluminum cans price per lb—whether you’re an individual collector or a small business with a steady stream of empties.

| Step | Why It Matters | Actionable Advice |

|---|---|---|

| Sort and Clean Thoroughly | Clean, uncontaminated cans fetch higher prices and are accepted by more yards. | Rinse out cans to remove sticky residue and food scraps. Remove any labels or tape, as adhesives can lower value or cause rejection at some facilities. |

| Crush or Flatten Cans | Crushed cans take up less space, making transport easier and sometimes increasing value. | Use a can crusher or stomp cans flat before bagging. This also helps you store more cans between trips. |

| Understand Scrap Yard Terminology | Knowing the difference between 'clean' and 'dirty' aluminum helps you sort for the best price. | Ask your local recycler about their grading standards. Clean cans (no residue, no attachments) almost always earn more per pound than mixed or dirty aluminum. |

| Shop Around for Rates | Prices can vary widely by region and recycler—even day to day. | Call or check websites for local recycling centers and scrap yards. Compare offers and ask about minimum weight requirements or bonus programs. |

| Sell in Bulk | Larger loads often qualify for higher rates per pound. | Save your cans until you have a substantial amount—such as 100 lbs or more. Some yards offer premiums for bulk drop-offs, making each trip more profitable. |

| Know Local Laws and Deposit Programs | States with bottle bills offer fixed returns per can—sometimes much higher than scrap value. | Check if your state has a container deposit program (like 5–15 cents per can). If so, you could earn much more than the standard per-pound rate. |

Let’s put it into perspective: At an average aluminum cans price per lb of $0.56, collecting 200 lbs could earn you about $112. However, in states with higher rates or deposit laws, your return could be even greater (The Penny Hoarder). Since it takes roughly 32 cans to make a pound, 200 lbs equals about 6,400 cans—so organizing a community or workplace collection can really add up!

"A little extra effort—cleaning, sorting, and selling in bulk—can significantly increase your aluminum can recycling profits."

By following these practical steps, you’ll not only boost your earnings but also make a positive impact on the environment. Next, we’ll dive into how aluminum pricing shifts for different industrial alloys and why that matters for specialized buyers and sellers.

Ever wondered why two blocks of aluminum—both shiny and lightweight—can have such different price tags? If you’re sourcing for a manufacturing project, or comparing quotes for a custom extrusion, you’ve likely noticed that the 6061 aluminum price per pound isn’t the same as for 2024 or other industrial alloys. Let’s break down why alloy choice matters, how it impacts cost, and what you should expect when planning your next purchase.

Not all aluminum is created equal. Industrial aluminum alloys are grouped by series—like 2xxx, 6xxx, and so on—each with unique elements added to pure aluminum. These alloying elements, such as copper, magnesium, and silicon, give the metal specific properties for strength, corrosion resistance, and machinability. But they also change the price per pound.

| Alloy | Main Alloying Elements | Key Properties | Typical Applications | Price Range (per kg) |

|---|---|---|---|---|

| 6061 | Magnesium, Silicon | Good weldability, corrosion resistance, machinability; moderate strength | Structural components, frames, extrusions, automotive, marine | $1.8–$3.0 |

| 2024 | Copper, Magnesium | High strength, lower corrosion resistance, fair machinability | Aerospace, high-stress parts, military, structural fittings | $4.8–$5.6 |

Prices are indicative and may vary by region, supplier, and market conditions. For the latest, consult your supplier or industry price feeds.

For a deeper dive into the performance and pricing differences, see the detailed comparison at Tuofa CNC Machining.

Imagine you’re designing a lightweight bike frame, a custom enclosure, or a load-bearing bracket. Your alloy choice will influence not just the performance, but also the total project cost. Here’s a quick checklist to guide your decision:

Even the best alloy can underperform if quality is inconsistent. That’s why working with a trusted supplier is crucial—especially for custom or high-tech needs. Shengxin Aluminum, for example, offers a full range of industrial aluminum profiles, from standard 6061 extrusions to specialized alloys for demanding applications. With decades of experience, advanced production technology, and strict quality controls, they ensure you get the precise alloy and performance you require, every time. Whether you need mill finish profiles for construction or custom-engineered solutions for rail transit and new energy vehicles, Shengxin delivers reliability and expertise at scale.

Understanding the nuances of alloy pricing and selection empowers you to make smarter sourcing decisions—balancing performance, durability, and cost. Next, we’ll explore how the physical form of aluminum—plate, ingot, extrusion, or sheet—also plays a key role in determining the final price per pound.

Ever noticed how the price tag on a thick aluminum plate is higher than that on a simple ingot? Or wondered why custom extrusions cost more than basic sheets? If you’re sourcing aluminum for a project—whether it’s a one-off prototype, a large construction job, or a high-tech industrial part—the physical form of aluminum matters just as much as the alloy itself. Let’s break down why the aluminum plate price per lb and aluminum ingot price per lb can differ so widely, and how understanding these differences helps you make smarter, more cost-effective choices.

Imagine aluminum’s journey from raw material to finished product. Each step—casting, rolling, extruding, machining—adds value, complexity, and cost. Here’s how the most common forms compare:

| Form | Description | Processing Level | Typical Price per lb* | Best Use Cases |

|---|---|---|---|---|

| Ingot | Large, cast blocks of raw aluminum; basic shape, minimal processing | Low | Lowest (close to LME base price) | Remelting, alloying, further processing |

| Sheet | Thin, flat pieces rolled from ingots; used in fabrication and stamping | Medium | Higher than ingot | Automotive panels, packaging, roofing |

| Plate | Thicker, flat aluminum slabs; require more rolling and finishing | Medium-High | Higher than sheet | Machined parts, structural components, aerospace |

| Extrusion | Custom shapes pushed through a die; can be complex or simple | High | Highest (especially custom) | Window frames, rails, heat sinks, industrial profiles |

*Exact prices vary by alloy, order volume, and supplier. Always request current quotes for your specific needs.

When you see a quote for aluminum plate or extrusion, what’s actually included in that number? Here’s a simplified breakdown:

"The further you move from raw ingot to finished product, the more value—and cost—is added per pound."

When your project requires complex or custom aluminum forms, working with a vertically integrated supplier can make a real difference. Shengxin Aluminum, for example, manages the entire process—from casting and extrusion to finishing and CNC machining—under one roof. This means:

In short, understanding how the physical form of aluminum shapes its price per pound allows you to balance performance, budget, and project requirements. As you plan your next purchase—whether it’s a basic ingot or a high-precision extrusion—consider not just the raw material cost, but the value added by every processing step. Next, we’ll explore how global market benchmarks like the LME influence these prices and what it means for your buying strategy.

Ever checked the price of aluminum and wondered, “Who decides this number—and why does it change so often?” If you’ve heard terms like LME aluminum price per lb or “Midwest Premium,” you’re already brushing up against the world of market benchmarks. These benchmarks are the backbone of aluminum pricing globally, shaping what both buyers and sellers pay or receive—whether for raw ingot, finished products, or scrap. But how do they actually work, and what do they mean for your bottom line?

Imagine you’re at an auction where the opening bid sets the tone for every deal that follows. That’s what the London Metal Exchange (LME) does for aluminum. As the world’s leading marketplace for trading industrial metals, the LME publishes daily prices based on real-time, global supply and demand. This price—quoted in U.S. dollars per metric ton—serves as the universal reference point for contracts, spot deals, and hedging strategies across the industry.

So, when you see aluminum quoted at a certain price per pound, it almost always starts with the LME’s latest figure, converted from metric tons to pounds for local markets.

Sounds simple? Here’s where it gets interesting. The LME price is just the base. In real transactions, additional premiums are added to reflect:

For example, in the U.S., the Midwest Premium is a widely tracked regional adjustment reflecting local delivery and market conditions. In other regions, similar premiums account for duties, logistics, or even political events. These premiums can shift quickly based on trade policy changes, supply chain disruptions, or sudden demand spikes (CME Group).

Let’s put it all together. The final price you pay—or receive—for aluminum is a combination of:

| Component | Description | Example Impact |

|---|---|---|

| LME Base Price | Global benchmark, sets the starting point | e.g., $1.17 per lb (converted from LME metric ton price) |

| Regional Premium | Reflects local logistics, tariffs, and supply-demand | e.g., Midwest Premium adds $0.40+ per lb in the U.S. |

| Processing/Conversion | Cost to turn ingot into sheet, plate, extrusion, etc. | Varies by form and complexity |

| Supplier Margin | Markup for distribution, service, or custom fabrication | Depends on supplier and order size |

For buyers, understanding this breakdown is crucial for budgeting, negotiating contracts, and timing purchases. For sellers or recyclers, it helps explain why local prices track—yet often differ from—the LME aluminum price per lb.

Whether you’re buying on the spot market or locking in a long-term contract, market benchmarks like the LME provide transparency and a common reference point. They allow both sides to track price movements, hedge against volatility, and ensure fair value—no matter where or how the deal is made. In times of market disruption, such as new tariffs or supply chain shocks, these benchmarks become even more important for managing risk and staying competitive.

In summary, the LME and other aluminum market benchmarks are much more than numbers on a chart—they’re the foundation of global pricing. By understanding how base prices and premiums interact, you’ll be better equipped to navigate negotiations, spot opportunities, and make confident buying or selling decisions. Next, we’ll show you where to find accurate, up-to-date aluminum prices for your specific needs.

Ever found yourself asking, “Where can I check the local aluminum price per lb before I sell my scrap or place a big order?” With prices shifting daily and so many sources online, it’s easy to feel overwhelmed. Whether you’re a homeowner with a trunk full of cans, a business sourcing raw material, or just someone watching the metals market, knowing where to find aluminum prices—and which sources to trust—can make all the difference.

Imagine you haul in a load of aluminum, expecting a certain payout, only to find rates have dropped—or that another yard nearby pays more. Or maybe you’re a buyer who needs to lock in the best deal for a project. The key? Always use accurate, current, and local data. Here’s how you can make sure you’re getting the right information for your needs.

Let’s break down the main sources, tailored to different types of users:

| Who You Are | Best Sources | Why Use Them? |

|---|---|---|

| Scrap Sellers & Recyclers |

|

Reflects actual prices paid for your material, including local premiums and yard-specific adjustments. |

| Industrial Buyers & Fabricators |

|

Ensures you’re budgeting with accurate, market-reflective prices for bulk or specialty orders. |

| Market Watchers & Investors |

|

Gives a big-picture view of trends, volatility, and market-moving events. |

| Hobbyists & DIYers |

|

Helps you gauge fair value for small quantities or unique items in your area. |

Tip: Always verify whether prices are for clean, sorted aluminum or mixed/dirty scrap—this can make a big difference in your payout.

In the end, the best price is the one that’s current, local, and fits your specific needs. Whether you’re dropping off a few cans or negotiating a bulk order, using the right resources ensures you get fair value and avoid surprises. With a little research and by checking multiple sources, you’ll feel confident every time you buy or sell aluminum.

Next, we’ll wrap up with a summary of the key takeaways from this guide and show how a smart approach to aluminum pricing can lead to better decisions—no matter your role in the value chain.

When it comes to navigating the world of aluminum, knowledge truly is power. Have you ever wondered why prices seem to swing from week to week, or why one supplier’s quote is so different from another’s? As you’ve seen throughout this aluminum price per lb guide, the answer lies in a complex but understandable web of global forces, local dynamics, and material-specific details.

"The smartest buyers and sellers are those who blend real-time data, market awareness, and a clear understanding of grades and processing costs."

Imagine you’re sourcing material for a high-stakes project—maybe a rail transit component, a precision extrusion for a new energy vehicle, or a custom architectural profile. In these cases, price is only one part of the equation. Consistent quality, technical expertise, and reliable service are just as important as a competitive rate.

That’s why partnering with a reputable supplier like Shengxin Aluminum can make all the difference. With advanced production capabilities, strict quality controls, and deep experience in both commodity and specialty alloys, Shengxin delivers not just material, but peace of mind. Whether you need standard profiles or custom-engineered solutions, their commitment to quality and customer support ensures you get the right product, on time, every time.

With the right information and partners, you’ll be equipped to make smarter, more profitable decisions in the ever-evolving aluminum market. The next time you’re faced with a pricing puzzle, remember: a little research, the right questions, and a trusted supplier go a long way toward ensuring success.

The value of 1 lb of aluminum varies depending on its grade and cleanliness. Clean aluminum cans typically fetch around $0.45–$0.75 per pound at scrap yards, while other forms like extrusions or clean sheet aluminum may earn higher rates. Local market demand and scrap yard policies also influence the exact payout.

Industrial aluminum alloys such as 6061 and 2024 command different prices due to their composition and applications. For example, 6061 alloy is generally more affordable and widely used, while 2024 is pricier due to its strength and use in aerospace. Always check with your supplier for the latest rates, as alloy and form factor impact the final price.

The current spot price of aluminum fluctuates daily based on global benchmarks like the London Metal Exchange (LME) and regional premiums. Checking reputable sites such as Daily Metal Price or Kitco provides real-time updates. Local scrap yards may offer different rates, so always confirm with your preferred location.

To maximize your payout, sort and clean your aluminum cans, sell in bulk, and compare rates at multiple local scrap yards. Some states offer deposit programs that pay a fixed amount per can, which can be more profitable than selling by weight. Timing your sale when prices are higher can also increase your earnings.

Reliable aluminum price data can be found on metal exchange websites, local scrap yard listings, and industry benchmark platforms like Fastmarkets. For industrial orders, contact reputable suppliers or distributors directly for current quotes tailored to your needs.

Интернет Сервис

Интернет Сервис 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360